Customized China Metal Casting Factory Stainless Steel Precision Lost Wax Investment Casting

Basic Info

| Model NO. | OEM |

| Application | Machinery Parts |

| Material | Stainless Steel |

| Surface Preparation | Sand Blast |

| Surface Roughness | Ra6.3 |

| Machining Tolerance | +/-0.02mm |

| Standard | ASME |

| Certification | CE, RoHS, ISO 9001:2000, ISO 9001:2008 |

| Product Name | Customized China Stainless Steel Precision Lost Wa |

| Technology | Precision Investment Casting |

| Surface | Sand Blasting, Polishing, Elctropolishing |

| Casting Tolerance | CT4-CT6 |

| Inspection | 100% Visual Inspection |

| Lead Time | 30 Days |

| Package | Cartons+Wooden Case/Pallet |

| Certificates | ISO9001:2015 |

| MOQ | 100 PCS |

| Transport Package | Bubble Bag+Cardboad Carton+Pallet |

| Specification | OEM |

| Trademark | Hongsheng |

| Origin | China |

| HS Code | 8302410000 |

| Production Capacity | 100tons/Month |

Packaging & Delivery

Package size per unit product 30.00cm * 30.00cm * 40.00cm Gross weight per unit product 1.500kgProduct Description

https://editor.made-in-china.com/home?id=0

Product Description

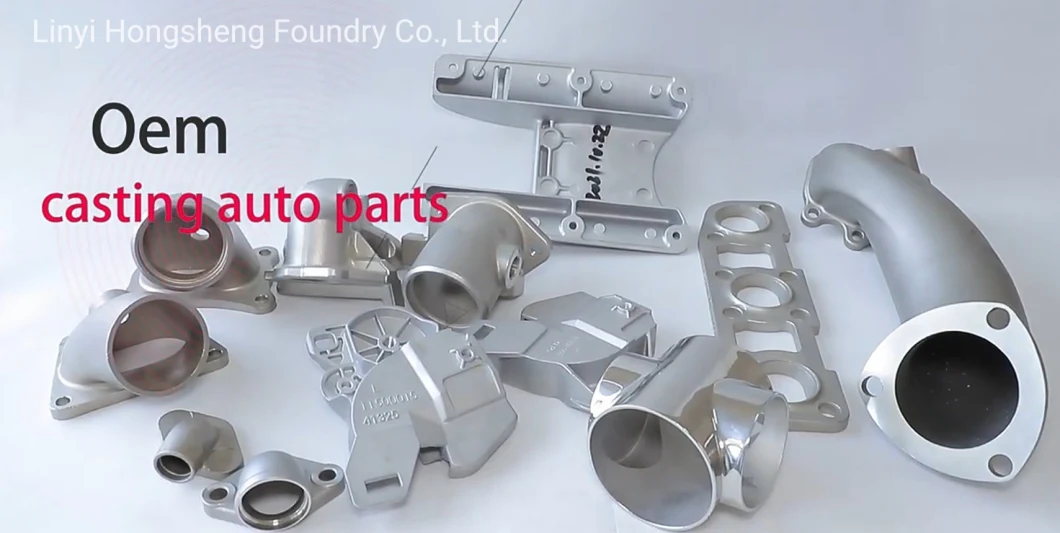

Customized china Metal Casting factory Stainless Steel Precision Lost Wax Investment Casting

| R&D | Softward: Solidworks, CAD, Procast, UGDevelopment cycle of samples: 25-35 days |

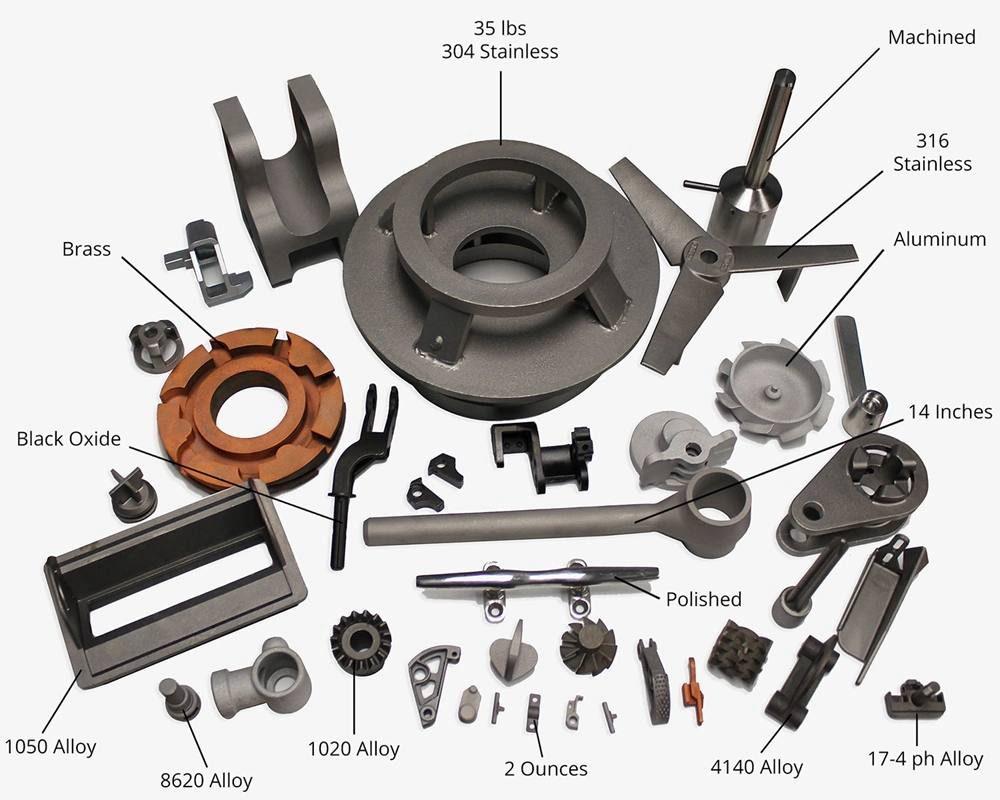

| Materials | Stainless steel: 304/304L, 316/316L, 410/416 etcDuplex stainless steel: 2250, 2507, Zeron 100 etcCarbon steelAlloy steel |

| Technical Parameter | Part weight: 2g to 30kgsMax dimension : 600mm for diameter or lengthMin wall thickness : 1.5mmCasting roughness: Ra3.2-6.4 Machining roughness: Ra1.6Tolerance of casting: CT6Inner core: ceramic core, urea core, water soluble wax core. |

| Heat treatment | Normalzing, Tempering, Quenching, Annealing, Quenching & Tempering, Caburization, Solution treatment. |

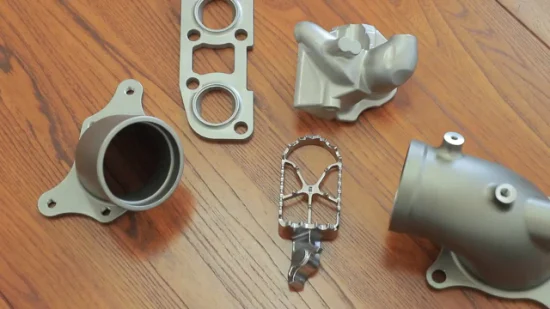

| Surface treatment | Polishing, bead blasting, zinc plating, hot dip galvanized, nickel plating, passivation, Electro-polising, mirror polishing, Brush polishing, PE coating, Powder coating, etc |

| Inspection | Cleanliness inspection, X-Ray radiographic inspection, CMM inspection |

| Production capacity | More than 120 tons per month |

| Quality Certificates | ISO9001; ISO14001 |

Linyi Hongsheng Foundry located in Shandong Province, China.

We specialized in silica sol investment casting with more than 20 years and covers 100,000 square meterswith 500 employees. Our production management and quality control system fully meet the request of ISO 9001:2015, certified by TUV Rheinland. Hongsheng Produces a wide variety of high-grade precision casting and machined parts in stainless steel, carbon steel, alloy steel..the main fields including high-speed rail, automobile industry, marine equipment, medical instrument, machinery parts, construction hardware, pump and valve parts...etc

Advantages of Stainless Steel Castings

Stainless steel investment castings are used across a wide range of industry sectors for the following reasons:

- Excellent Corrosion Resistance: Chromium is used as an alloying element in stainless steel which helps improve its anti-corrosive properties. Unlike carbon and alloy steel, stainless steel castings require little or no additional surface finishing. This one reason why stainless steel investment cast parts are used in industrial components such as valves, pumps, and other parts where corrosion resistance is critical.

- Exceptional Visual Quality: Grade A visual appearance is possible for investment cast parts that require high visual quality.

- Surface Finishes: 120 RMS or better is easily achieve.

- Near Net Shape Parts: Avoid long run time machine parts using near net investment cast parts.

- Close Tolerances: ±.005 inch per inch tolerance levels can be achieved.

Secondary Operations and Treatment of Investment Castings We Offer

| Polished zinc plating, nickel plating, electroplating, Chrome plating | |

| Anodizing, phosphating, acid treatment, polishing | |

| High precision CNC machining | |

| Broaching, milling, drilling, tapping | |

| Surface grinding, sand blasting, powder coating | |

| Heat treatment |

Package

FAQQ1: What is our payment term?

A:T/T, Paypal. Q2: How can we quote for you?

A: Please email us enquiry with all technical drawings you have, such as material grade, tolerance, mechanicalproperties, heat treatment, requirements, etc. Our specialized engineers will check and quote for you within 24 hours. Q3: Which product are often processed by your company ?

A: Auto parts,machinery part, marine part, Kitchen parts, Agricultural parts.Q4: Which material are often used ?

A: Stainless steel. alloy steel, carbon steel, aluminum, copper.Q5: Which finish you can provide ?

A:Sand blasting, Tumbling, Polishinh, Electro-polishing, Mirror Polishing, Powder coating, Electrophoresis, ETC.Q6: What is the MOQ ?

A: Based on the product, normal 100 pcs.Q7: Can we make the samples?

A: Is Available, 15-20days for sampling.Q8: How about for the lead time?

A: Normally about 35 days for mass production, pls inform us if it is urgent order.